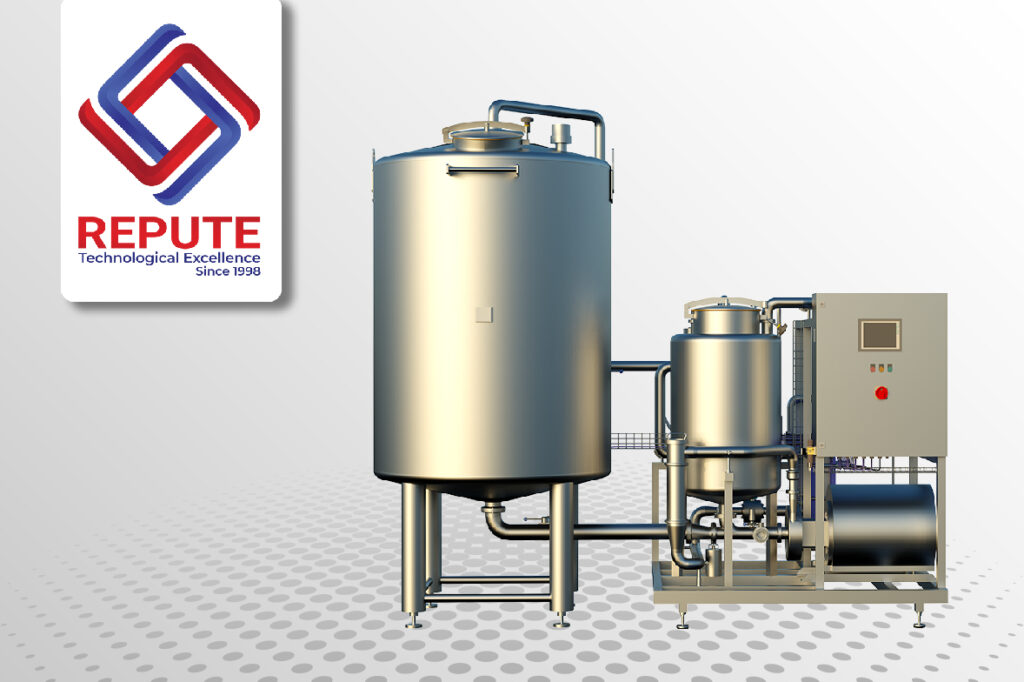

Maintaining a hygienic and clean environment is vital for ensuring the quality and purity of a product. Cleaning is the first step in production, and manual cleaning on a large scale is quite a task. The equipment cannot be dismantled and cleaned manually. This is where the Cleaning-in-place (CIP) mechanism comes into action.

The primary purpose of the CIP system is to clean the contact surfaces of the equipment by passing chemicals like various detergents and disinfectant solutions, further rinsing them with water.

CIP systems are exceptionally useful for facilities that run several different products through the same filling machine or when different products processed in the same plant and the single product handled with the system also need to be cleaned through CIP system to avoid any contamination. The CIP system is a hassle-free, quick, efficient method of cleaning and can be recorded.

To understand the procedure in detail, let’s explore the different steps and circuits available in the CIP system:

CIP systems are available with single, double and multi circuit’s to clean different size off equipments to be cleaned in different processing and filling plants.

Based on the process and the products handled in the plant, no of steps are decided. Generally 3, 5 and 7 steps are adopted. Let us explore as 7 step CIP sequence as given below.

1.The pre-rinse

The first step of the CIP sequence is pre- rinse. Where potable plant water, de-ionized water (DI), reverse osmosis (RO) water (as may be the case), or the final rinse solution from the previous cleaning cycle (from recuperation tank) is passed through the lines, fittings, and internal surfaces of the equipment. This helps to remove most of the remaining product residue and melts thick fat prior to the formulated alkaline wash. Pre-rinse timing can be decided based on the product handled in the system and, depending on the equipment that needs to be cleaned.

2.Caustic wash

Alkaline detergents such as caustic soda, sodium hydroxide, or NaOH (detergents with a pH range of 0.5 to 2.0%) are mixed with water at a typical temperature of 55 to 90°C and circulated to remove fats and proteins. To maximize the chemical removal process and for easier rinsing, air blows are often used after the caustic wash. This caustic solution can be stored and used later for the next cycle.

3.Hot Water

During this sequence hot water will be used. This is done to purge out the residual alkaline solution and additional loose dirt. Timing for this sequence will be depending upon the product and the size of the equipment. The inner contacts of the equipment are then monitored to check if any chemical residue is detected (this can be monitored with the help of pH value, conductivity, etc.).

4.Acid wash

Acid solution (with a concentration of 0.5-2%), with a temperature range between 20 and 70°C, is circulated through the inner contacts of the equipment to neutralize the alkali effect of the caustic wash. It also removes and dissolves mineral and limescale deposits. The frequency of acid wash will depend on the food type and the water quality.

5.Hot water

During the filling machine CIP, this is done to purge out the residual acid solution and additional loose dirt. Timing for this sequence will be depending upon the product and the size of the equipment. The inner contacts of the equipment are then monitored to check if any chemical residue is detected (this can be monitored with the help of pH value, conductivity, etc.).

6.Hot water (at higher temperature)

The final wash ensures that there is no leftover material or chemical residue in the piping, tanks, heat exchangers, and other equipment of the filling machine. Clean potable water, DI, or RO water is used for this process. The rinse time may vary from 5 to 20 minutes. The final rinse water can be recovered and reused in the next CIP cycle. The chemical residue in this final rinse water can aid in an efficient cleaning for the next pre-rinse. A final air blow is initiated to remove any remaining moisture.

7.Sanitizing rinse

In this sequence of the CIP sequence is sanitizing rinse. Where potable plant water, de-ionized water (DI), reverse osmosis (RO) water (as may be the case).This helps to sanitize the object to be cleaned by cooling down the hot surface to ambient temperature. As this rinse conducted after the final wash the clean water coming out of this sequence can be used for pre rinse.

Choosing a CIP cleaning technology over hand cleaning may seem like a big investment. better production with less time spent on cleaning operations, improved consumer satisfaction, and better employee productivity. With the CIP cleaning system, employees will be able to spend less time on monotonous duties. A well-designed and properly built CIP system is an investment in the security of your brand and the people who use the brand.